PRODUCTS & SERVICES

SandPro is driven by innovation

and market awareness

Sand Management

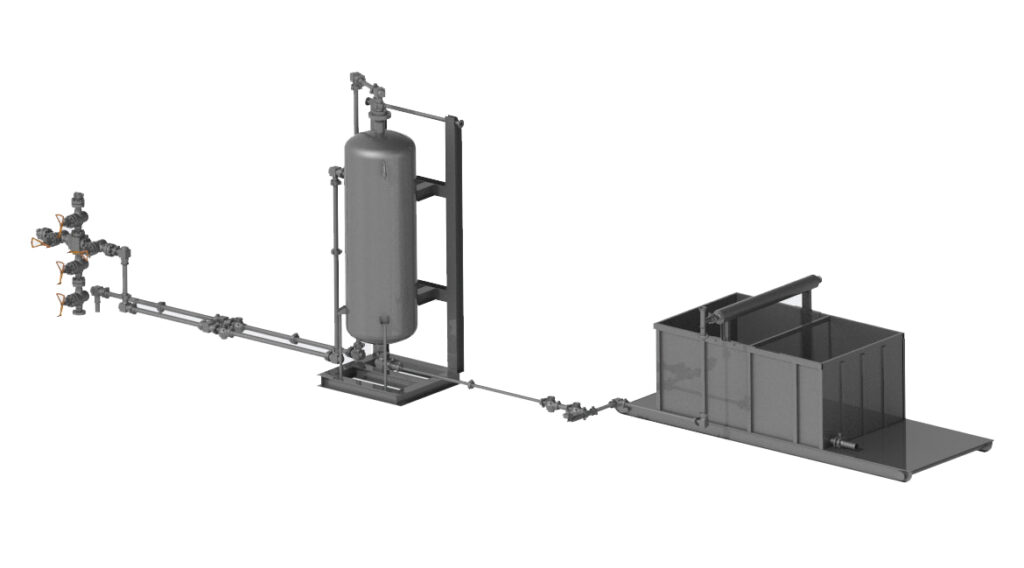

• CBT UNIT - BULK AND TEST CTB SAND FILTRATION UNITS

Alternative to vessels on individual wells by flowing wells to a central tank battery as a bulk and test design strategy.

Reduces footprint on location while maintaining maximum sand removal and quantification from each well. Utilizing patented baffle plates, the unit creates an upward hydro-turbulence causing a harmonic vibration. This vibration causes solids to separate from the fluid as fluid and gas exit the unit.

As fluid enters the vessel it is directed to the bottom chamber where heavier solids are removed using centrifugal fluid movement. As the fluid moves upward to the top chamber it passes through the patented baffle system where fluid dynamics are changed, equalization occurs and harmonic resonance is created.

These key design features are crucial to eliminating collection of solids on the filter. Filters are customer designed in many sizes to fit all phases of the flowback and production operations, utilizing 100m, 200m or 300m filters to stop the finest of solids.

A DIFFERENT TYPE OF FLOWBACK

Utilizes operator facilities to separate fluids and gases rather than traditional flowback packages.

Drastically reduced rental costs

Eliminate potential environmental consequences of heavy solids through flowline

Eliminate cost of repairing washed flowlines

Eliminate the need of costly cleanouts and lost production

Environmental-Social-Governance

- CUSTOMER ADVANTAGES

- KEY FEATURES

- TECHNICAL SPECIFICATIONS

- CUSTOMER ADVANTAGES

Reduced LOE

Full sand capture

LOE reduced down time

Eliminates need for facility cleanouts

Environmental-Social-Governance

Non-atmospheric releases

90% reduction in fuel and emissions

90% reduction of human wellsite exposure

- KEY FEATURES

Drastic cost reduction over individual well strategy

Positive barrier

Self-cleaning

Large volume

Retention time and fewer dumps

Simplistic reliable design

- TECHNICAL SPECIFICATIONS

500 PSI LEAVE BEHIND FILTER UNIT

Max Flow (Fluid): 7,500 @ 2”, 9,500 @ 3”

Max flow (Gas): Up to 10MCF

Efficiency: 100% @ 100 MESH

Size: 96”x36”

Capacity: 11.5 BBL’s

I/O: 2”- 3”- 4” and Flanged available

720 PSI LEAVE BEHIND FILTER UNIT

Max Flow (Fluid): 7,500 @ 2”, 9,500 @ 3”

Max flow (Gas): Up to 10MCF

Efficiency: 100% @ 100 MESH

Size: 96”x36”

Capacity: 11.5 BBL’s

I/O: 2”- 3”- 4” and Flanged available

1440 PSI FILTER UNIT

Max Flow (Fluid): 10,000 @ 2”, 14,500 @ 3”

Max flow (Gas): Up to 10MCF

Efficiency: 100% @ 100 MESH

Size: 96”x48”

Capacity: 22 BBL’s

I/O: 2”- 3”- 4” and Flanged available

2000 PSI FILTER UNIT

Max Flow (Fluid): 10,000 @ 2”, 14,500 @ 3”

Max flow (Gas): Up to 10MCF

Efficiency: 100% @ 100 MESH

Size: 96”x48”

Capacity: 22 BBL’s

I/O: 2”- 3”- 4” and Flanged available