PRODUCTS & SERVICES

SandPro is driven by innovation

and market awareness

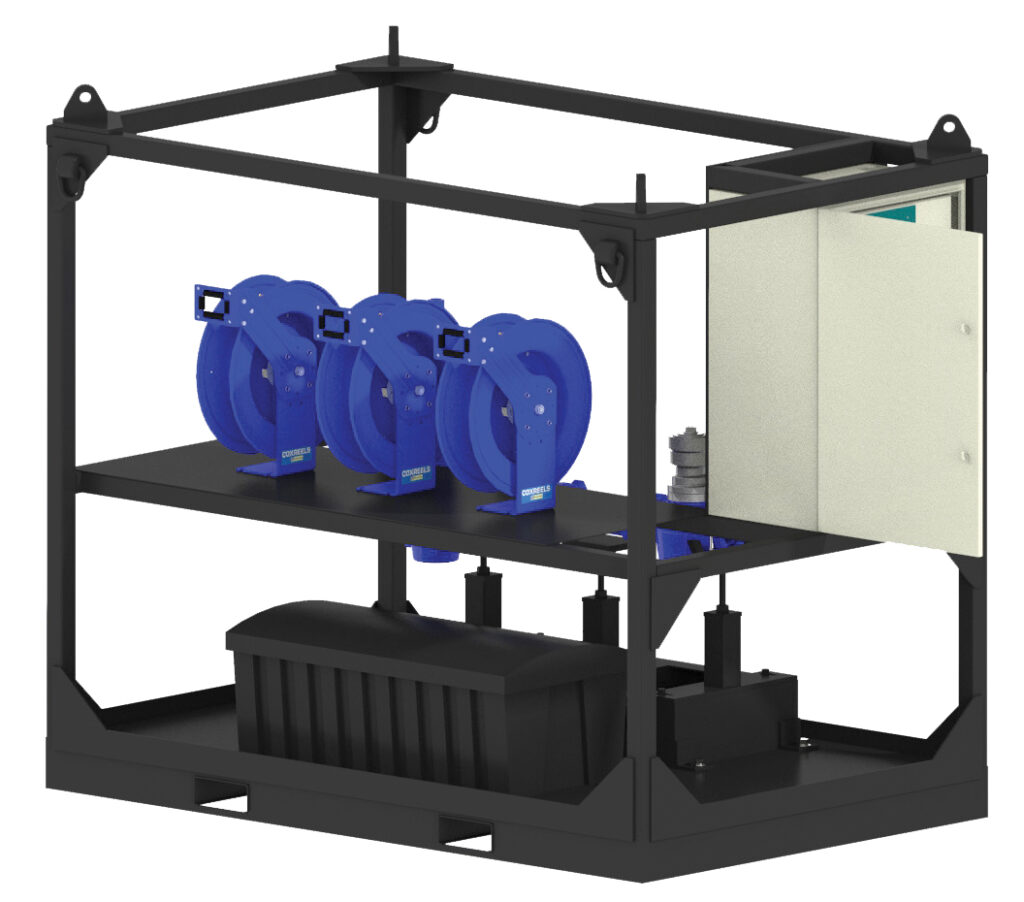

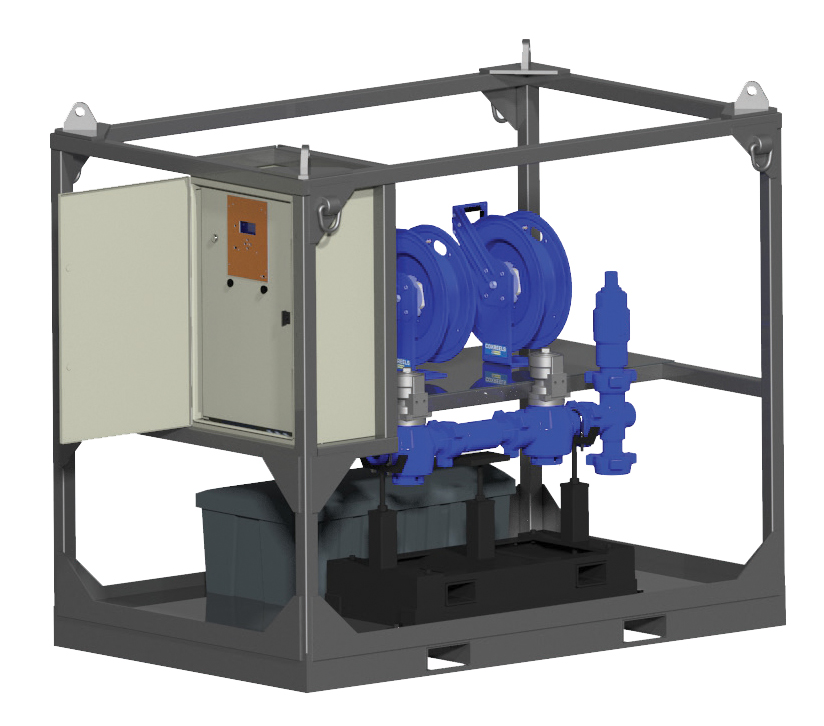

• mSAND - AUTOMATED BLOW DOWN SYSTEM

The mSand system is designed to reduce

wellsite exposure and increase efficiencies

during blow down operations.

FEATURES:

Manual, remote and automated operations.

Suitable for Temporary or Permanent applications.

Sequential operation of opening/closing of complete system.

Sensor monitored dual isolation leak detection.

Compatible with SSV/ESD valve solutions.

UL 508A Listed and NEMA 1, 3R, 4 and 12 Encloser.

Communication: SCADA (ModBus Protocol) and 2-way Telemetry.

Available in Standard or NACE Service

ADVANTAGES:

Reduced personnel exposure

Reduced OPEX by fewer well visits

Reduced maintenance costs by protecting the integrity of the valves

Easy installation, predictive operation with low operator training times.

Traceability of the entire operation through internal data storage.

Customized dump valve to minimize wear and reduce replacement costs.

COMPONENTS IDENTIFICATION:

Electro-hydraulic mSand Panel.

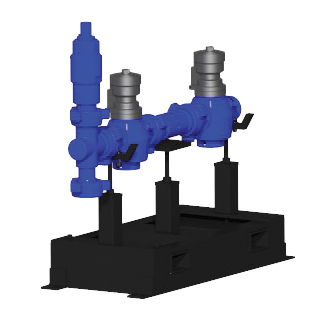

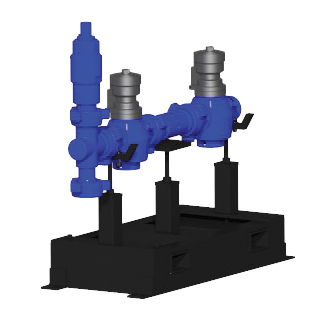

PV 1/2: 2” or 3” Pressure Transducers Class 1 Div.1

PV 1/2: 2” or 3” Plug/ball valves Hydraulic actuated with position switches (Standard).

CV-3 (CPO ON/OFF): Calibrated orifice ON/OFF Choke, hydraulic actuated with position switches (Included in the basic equipment).

DESCRIPTION OF OPERATION MODES:

AUTONOMOUS

▘High Inlet Pressure (PT3)

▘Differential Pressure (PT3-PT2)

▘Time Between Dumps

▘Dump Holding Period

▘Valve Seat Test (PV1/PV2)

MANUAL

▘Manual locally from the panel: Double-button operation sequence

REMOTE

▘Operation through SCADA (ModBus Protocol/Telemetry)

FAILSAFE

▘In the event of detection of a non-system fault, mSand will send a shutdown signal for well closing.

SPECIFICATIONS

Hydraulic outlet pressure: 2,000 PSI

Oil Volume: 2 gallon (7.57 L)

Electric Power Required: 120VAC

Temperature: -40°F to 185°F (-40°C to 85°C)

Communications: Modbus RS485 protocall

Contact Us

Office

24-hour Dispatch Number

+1 701-453-3443

careers@sandpro.com

Operation Hours

Monday-Friday

7:00 am - 5:00 pm

Send Us A Message

© 2022 SandPro LLC. All Rights Reserved. Privacy Policy.

Terms of Use • Privacy Policy