PRODUCTS & SERVICES

SandPro is driven by innovation

and market awareness

- SANDPRO

- PRODUCTS & SERVICES

- PRODUCTION

- mSAFE PRODUCTION

Production

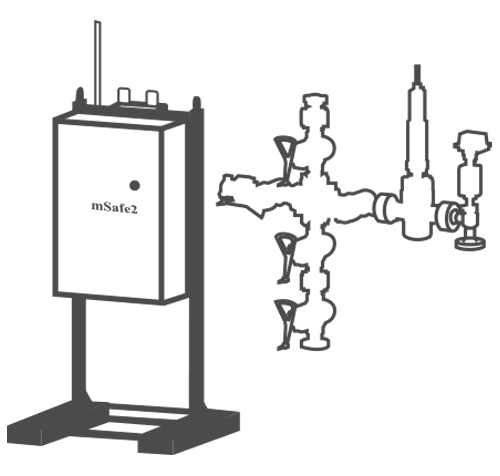

• mSAFE - PRODUCTION SSV/ESD SYSTEM

Manual, remote and automated operations

Implement condition-based monitoring and maintenance using valve status data communicated via SCADA, telemetry or downloaded from onboard memory

ELECTRONICALLY ASSISTED HYDRAULIC CONTROL

Field-proven in Latin and North America, the mSafe design integrates electronic

control and an electro- hydraulic pump to ensure the safety and performance of hydraulically actuated safety valves used in emergency shutdown applications.

The controller precisely and reliably manages valve position while monitoring hydraulic pressure in the actuator and actuator lines. The acquired data supports condition-based monitoring and maintenance practices that can significantly improve safety and performance.

Environmental-Social-Governance

- CUSTOMER ADVANTAGES

- KEY FEATURES

- TECHNICAL SPECIFICATIONS

- CUSTOMER ADVANTAGES

CONDITION BASED MONITORING

The mSafe controller’s ability to acquire and communicate precise data on even small changes in hydraulic pressure supports condition-based monitoring and maintenance in many ways:

Predictive Valve Maintenance

Predictive maintenance is enabled by early detection of small operational anomalies. Partial stroke testing allows diagnosis of potential valve failure without stopping production and with zero emissions. Maintenance is reduced and easier to schedule, and production delays are minimized.

Acuator Pressure Stabilization

Pressure stabilization eliminates progressive valve closure and associated wear with mSafe monitoring and automatically compensating for temperature- induced variations.

Line Break Detection

Identifies gradual losses in pressure over time preventing hydraulic releases. Deviation from the pressure gradient prompts an mSafe programmable alarm or valve closure.

- KEY FEATURES

Monitors and regulates ESD actuator pressure

UL 508A Listed and NEMA 1, 3R, 4 and 12 Encloser

Hydraulic fluid leak detection system

Reduce wellsite visits

Partial stroke test

Full SCADA capability

- TECHNICAL SPECIFICATIONS

mSAFE PRODUCTION SYSTEM