- CUSTOMER ADVANTAGES

CONDITION BASED MONITORING

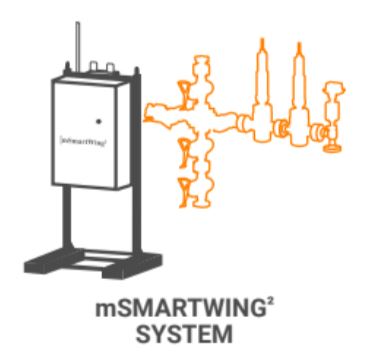

The mSmartWing2 controller’s ability to acquire and communicate precise data on even small changes in hydraulic pressure supports condition-based monitoring and maintenance in many ways:

Predictive Valve Maintenance

Predictive maintenance is enabled by early detection of small operational anomalies. Partial stroke testing allows diagnosis of potential valve failure without stopping production and with zero emissions. Maintenance is reduced and easier to schedule, and production delays are minimized.

Acuator Pressure Stabilization

Pressure stabilization eliminates progressive valve closure and associated wear with mSmartWing2 monitoring and automatically compensating for temperature-induced variations.

Line Break Detection

Identifies gradual losses in pressure over time preventing hydraulic releases. Deviation from the pressure gradient prompts an mSmartWing2 programmable alarm or valve closure.

Environmental-Social-Governance

- CUSTOMER ADVANTAGES

Verify Rod Rotation

Compatible with any rod rotator system

SCADA and Telemetry communications

Notification of any rod rotation failures

Arctic rated position sensors

UL 508A Manufacturing

Compatible with mAutoGrease+

- KEY FEATURES

24/7 Rod Rotator Monitoring

Reduce rod wear due to inefficient rotation

Reduce likelihood of lost production

Environmental-Social-Governance

24/7 monitoring to prevent environmental incidents

Reduced personnel HSE exposure and cost

- KEY FEATURES

Monitors and regulates ESD actuator pressure

UL 508A Listed and NEMA 1, 3R, 4 and 12 Encloser

Reduce wellsite visits

Hydraulic fluid leak detection system

Partial stroke test

Full SCADA capability and 2-way telemetry ability

Optimize flow rates with prompt choke adjustments

Available in sizes 21/16” 5K to 31/16” 10K

- TECHNICAL SPECIFICATIONS

Base: 35x32 inches (88x80 cm)

Accuracy of measurement: +-1%

Oil volume: 2 gallon (7.57 L)

Weight: 400 lbs. (181 kg)

Internal memory capacity: 6 months minute by minute via USB

Electric power required: 120VAC

Height: 69 inches (175 cm)

Response time: +-1%

Operating temperature: -40°F to 185°F (-40°C to 85°C)

Hydraulic outlet pressure: 300 to 2,000 PSI (20 to 138 Bar)

Communications: Modbus RS485 protocall

Contact Us

Office

24-hour Dispatch Number

+1 701-453-3443

careers@sandpro.com

Operation Hours

Monday-Friday

7:00 am - 5:00 pm

Send Us A Message

© 2022 SandPro LLC. All Rights Reserved. Privacy Policy.

Terms of Use • Privacy Policy